Ημερίδα στα πλαίσια του προγράμματος BREW2BIO I 28 April 2023 Waste biorefinery towards a sustainable circular bioeconomy @Agricultural University of Athens

Συμμετοχές σε επιστημονικά συνέδρια

Challenges in energy transition: Greek biorefinery development in the emerging biofuel industry

4th International Conference for Bioresource Technology for Bioenergy, Bioproducts & Environmental

Sustainability

Lake Garda Italy | 14–17 May 2023

Evanthia A. Nanaki, S. Kiartzis, A. Koutinas, N. Giannakis, E. Stylianou

(Poster presentation)

Biorefinery development using spent coffee grounds and orange peels combined with biodiesel production from microbial oil produced by Lipomyces starkeyi

WCCE11 – 11th World Congress of Chemical Engineering, Buenos Aires – Argentina – June 4-8, 2023

Stylianou E., Carmona Cabello M., Giannakis N., Leiva Candia D., Filippi K., Pateraki C., Argeiti C., Pilar Dorado M., Koutinas A.

(Poster presentation)

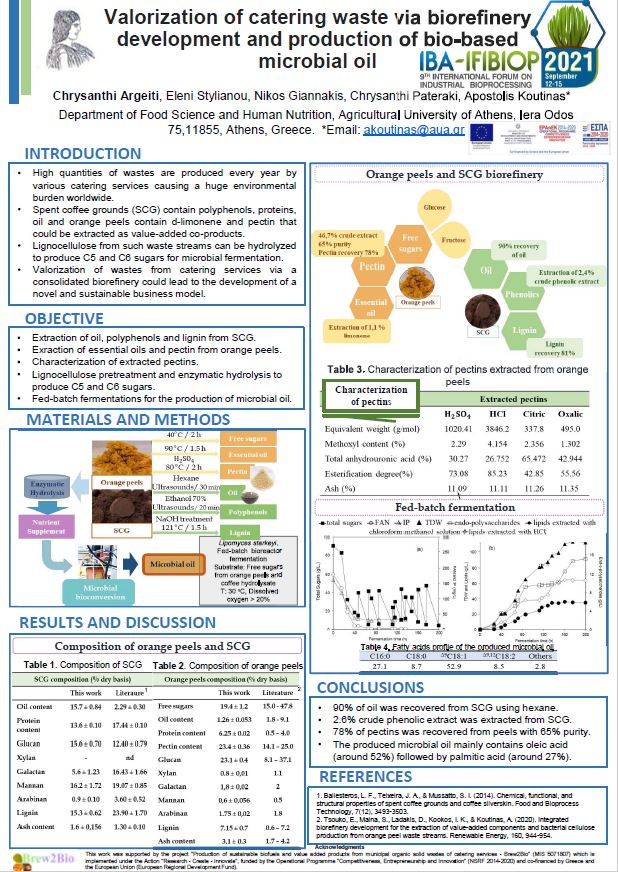

Valorisation of catering waste via biorefinery development and production of bio-based microbial oil.

9th International forum on industrial bioprocessing (IBA-IFIBIOP), 12-15 September, Saltillo, Mexico

Argeiti C., Stylianou E., Giannakis N., Pateraki C. and Koutinas A.

(Poster presentation)

Spent coffee waste and orange peel valorisation via biorefinery development for the production of value-added co-products and microbial oil

Environment workshops 2022, “Biorefineries, a key concept for achieving the sustainable development goals”, 30 March-1 April, Baeza, Spain

Pateraki C., Giannakis N., Argeiti C., Philippi K., Stylianou E. and Koutinas A.

(Poster presentation)

Spent coffee waste and orange peel valorisation via biorefinery development for the production of value-added co-products and microbial oil

International Conference on Renewable Resources and Biorefineries (RRB), 1-3 June 2022, Bruges, Belgium

Giannakis N., Argeiti C., Philippi K., Stylianou E., Pateraki C., and Koutinas A.

(Oral presentation)

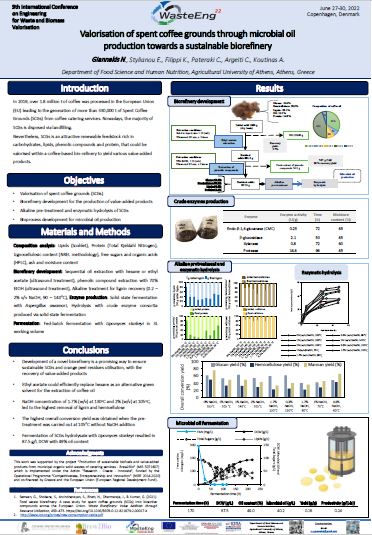

Valorisation of spent coffee grounds through microbial oil production towards a sustainable biorefinery

9th International Conference on Engineering for Waste and Biomass Valorisation, WasteEng 2022, 27-30 June, Copenhagen, Denmark

Giannakis N., Stylianou E., Filippi K., Pateraki C., Argeiti C., and Koutinas A.

(Poster presentation)

Hydrothermal liquefaction of spent coffee grounds targeting liquid biofuel intermediates

9th International Conference on Sustainable Solid Waste Management, 15-18 June 2022, Corfu, Greece

Liakos D., Triantafyllidis K., Chrysikou L. and Bezergianni S.

(Poster presentation)

Alkaline pretreatment of spent coffee grounds for microbial oil production using the oleaginous yeast strain Lipomyces starkeyi

9th International Conference on Sustainable Solid Waste Management, 15-18 June 2022, Corfu, Greece

Stylianou E., Giannakis N., Titiri E., Filippi K., Pateraki C., and Koutinas A.

(Oral presentation)

Δημοσιεύσεις σε επιστημονικά περιοδικά

Reinforcement of Urea Formaldehyde Resins with Pectins derived from Orange Peel Residues for the Production of Wood-Based Panels

Sustainable Chemistry for the Environment

Abstract: Pectin is a high molecular weight carbohydrate polymer that can be utilized in various applications in many sectors. The current study involved extracting pectin samples from orange peel residues and utilizing them as additives in water-based adhesive systems for producing composite wood panels. Three pectin types were used, named Pectin-A (extracted from orange peels with HCl), pectin-B (extracted from orange peels with H2SO4) and a commercial pectin called Pectin-C. The aim of the study was to examine the possibility of enhancing the efficacy of wood-based panels, such as particleboard, by strengthening amino resins like urea-formaldehyde resin (UF) using pectin samples. Three methods were utilized to incorporate the pectins into the adhesive systems: pectin 0.1% w/w dry/liquid resin added during the initial (1) and final (2) stage of the resin’s synthesis and pectin 0.1% w/w dry/liquid resin was incorporated into the glue mixture (3), which was then sprayed onto wood particles for the production of particleboard (PB) panels. It was found that pectins improve the performance of the final particleboards, especially when added during the UF resin synthesis. In addition, they may provide the adhesive and wood panel producers with a more environmentally friendly bio-additive for their products.

Spent coffee grounds and orange peel residues based biorefinery for microbial oil and biodiesel conversion estimation

Renewable Energy Journal

Abstract: A consolidated biorefinery was developed using spent coffee grounds (SCGs) and orange peel residues (OPR) to produce microbial oil and value-added co-products. Coffee oil and antioxidant-rich extracts were initially extracted from SCGs. Free sugars and pectin-rich extracts were obtained from OPR. Microbial oil production was evaluated using various oleaginous yeast strains cultivated on SCGs and OPR hydrolysates and free sugars. Microbial oil production was demonstrated in 30 L bioreactor scale using combined OPR-SCGs hydrolysate resulting in 56.7% (w/w) intracellular lipid accumulation and 0.32 g/(L∙h) productivity, corresponding to 68.1 g microbial oil production per 1 kg SCGs and 360 g OPR. Principal Component Analysis has been carried out to assess the similarity of microbial oil produced in this study and literature-cited oils considering the fatty acid methyl ester content. The biodiesel properties estimated based on predictive equations showed that they generally conformed with the limits set by European standards.

Optimisation of alkaline pretreatment of spent coffee grounds for microbial oil production by Cryptococcus curvatus

Biochemical Engineering Journal

Abstract: In a world of finite resources, the transition to a sustainable post-fossil resources economy is essential. Within this concept, spent coffee grounds (SCGs) could be used for the production of bio-based chemicals, biopolymers and value-added products. Lipids and phenolics were initially extracted from SCGs. Alkaline pretreatment of the remaining SCGs solids has been optimised in this study via Central Composite Design to maximise lignin removal and overall sugar to polysaccharide conversion yield. The optimal SCGs pretreatment conditions were 0.06% NaOH (w/v) and 99.5 oC resulting in 35.7% lignin removal at 60 min pretreatment duration with low cellulose and hemicellulose losses (ca. 2.5%). Enzymatic hydrolysis of the remaining SCGs alkaline pretreated solids resulted in 79.4% glucan, 74.5% mannan and 54.8% hemicellulose hydrolysis yield. The SCGs hydrolysate was used as fermentation feedstock in bioreactor cultures of Cryptococcus curvatus resulting in 36.1 g/L microbial oil with 0.25 g/g yield and 0.41 g/(L∙h) productivity. The total dry weight reached 62.7 g/L corresponding to 57.5% (w/w) intracellular lipid content. The microbial oil was rich in oleic acid (55.6%) followed by palmitic acid (18.9%) and stearic acid (14.0%). The proposed process led to the production of 7.81 g microbial oil per 100 g antioxidant and oil-free SCGs.